Factory Acceptance Test (FAT)

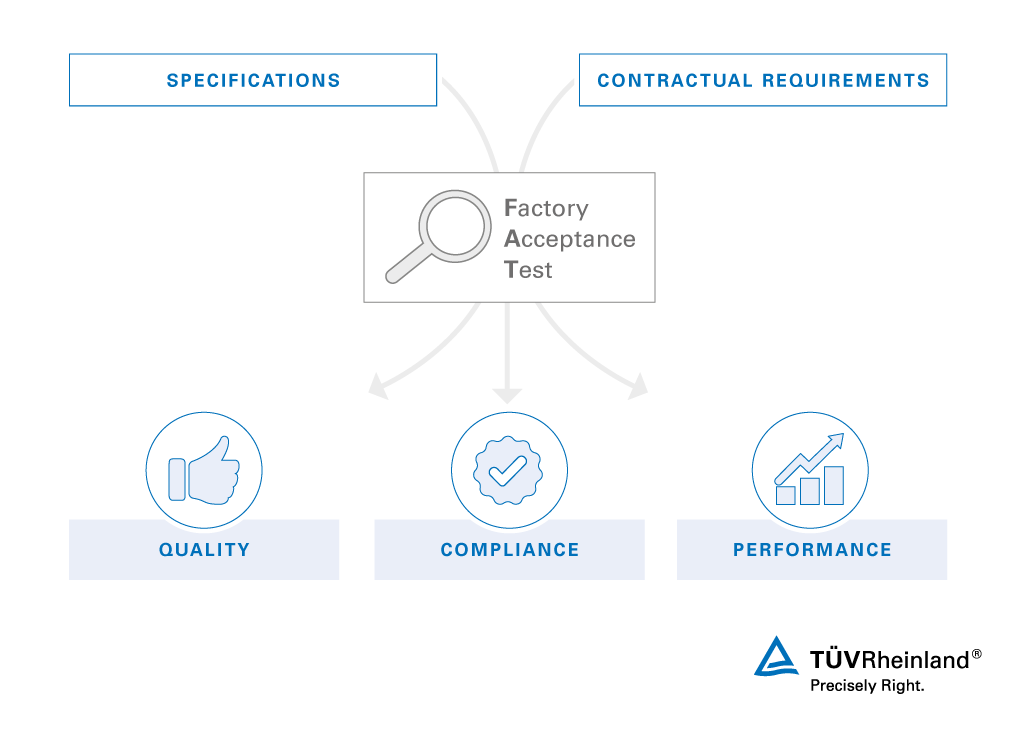

Ensure proven quality and compliance of your purchased equipment with our factory acceptance tests

As owner or operator of industrial facilities, successful and effective production depends on equipment that runs smoothly. Equipment has to meet quoted or contractually guaranteed specifications prior to delivery and final installation. Our factory acceptance testing services provide verification that all technical and quality requirements have been met before a component leaves the factory.

As an independent verification and certification company, we support your project or manufacturing process with extensive services along the supply chain. We ensure design specifications and prove the quality of your ordered equipment and components.

Contact us to ensure proven quality of your purchase and request a quote.

Safeguard equipment functionality and safety with the support of our factory acceptance experts

Our factory acceptance testing services offer extensive solutions to ensure the quality and compliance with specifications and contractual requirements for equipment and components. Make sure that your equipment or plant performs as expected under a full range of foreseeable conditions and avoid costly contractual penalties if you are a manufacturer or project downtimes if you are an operator.

Factory acceptance testing: Our contribution to your success

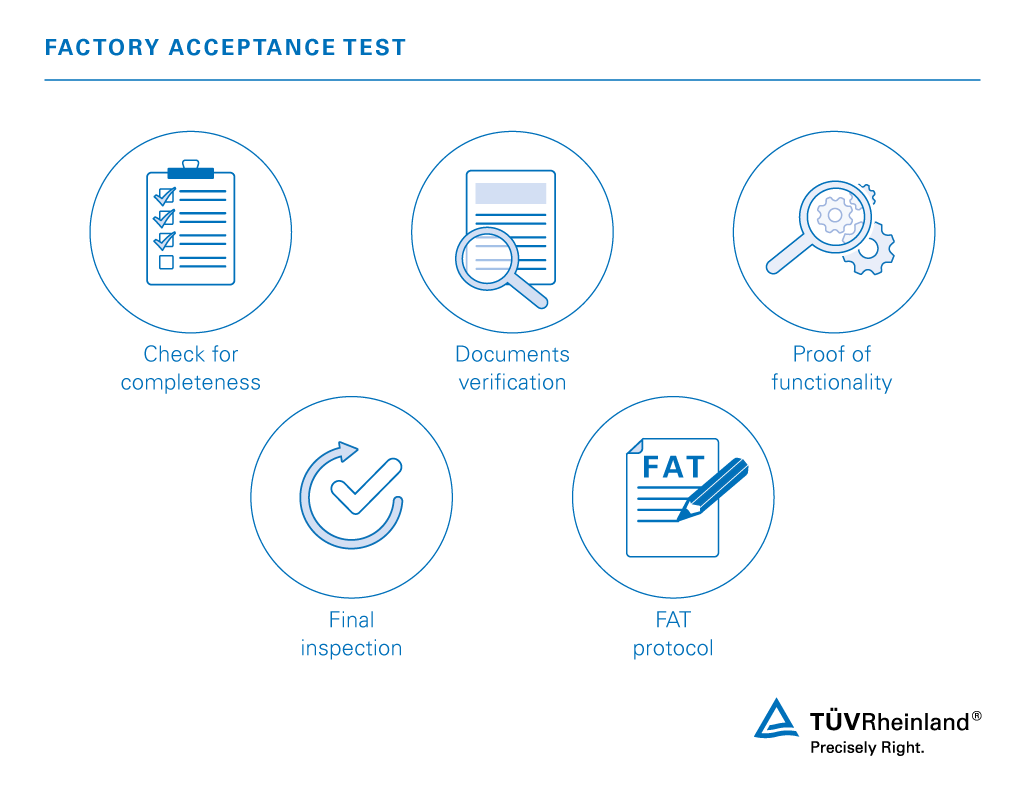

TÜV Rheinland experts offer manufacturers, EPC contractors, owners and operators a wide range of factory acceptance testing services including:

- Check for completeness

- Verification against contractual requirements

- Proof of functionality by either a conventional function test or simulation

- Final inspection of equipment and components

Services for proof of functionality

We use conventional function tests or simulation as part of a factory acceptance test to prove that your plant, its systems and its components meet contractual requirements. This includes the verification of documents such as manuals, plans, drawings as well as piping and instrumentation diagrams (P&IDs).

Final inspection services

We conduct the final inspection according to the specifications you approved. This may include checking conformity of drawings and documents, inspecting nameplate data, general appearance and verifying the quality of painting and coating.

TÜV Rheinland, your partner for acceptance testing

Think global, act local. TÜV Rheinland has the largest international network among German testing, inspection and certification companies. We offer a broad portfolio of tailored one-stop-shop solutions to cover all your needs along your supply chain.

You can trust our many years of experience on global projects and our expertise in assuring the quality of your industrial equipment, machinery, components, products and materials.

Contact our experts to discuss the factory acceptance of your purchased equipment.

5 easy steps to FAT testing

Value Added Services Along the Supply Chain

No matter in which sector you operate – TÜV Rheinland’s supply chain services supports clients during Vendor Selection, Production, Shipment and Installation.

We help you to select qualified suppliers, assure the quality of materials and components and avoid delays in delivery. Our experts audit, inspect or verify according to your Inspection Test Plans, your specifications or applicable international codes and standards.

We also assure safe and correct loading, shipment and discharge at any location worldwide to ensure that you receive proper and undamaged goods and materials. Finally, we supervise and monitor all construction site activities.

Contact